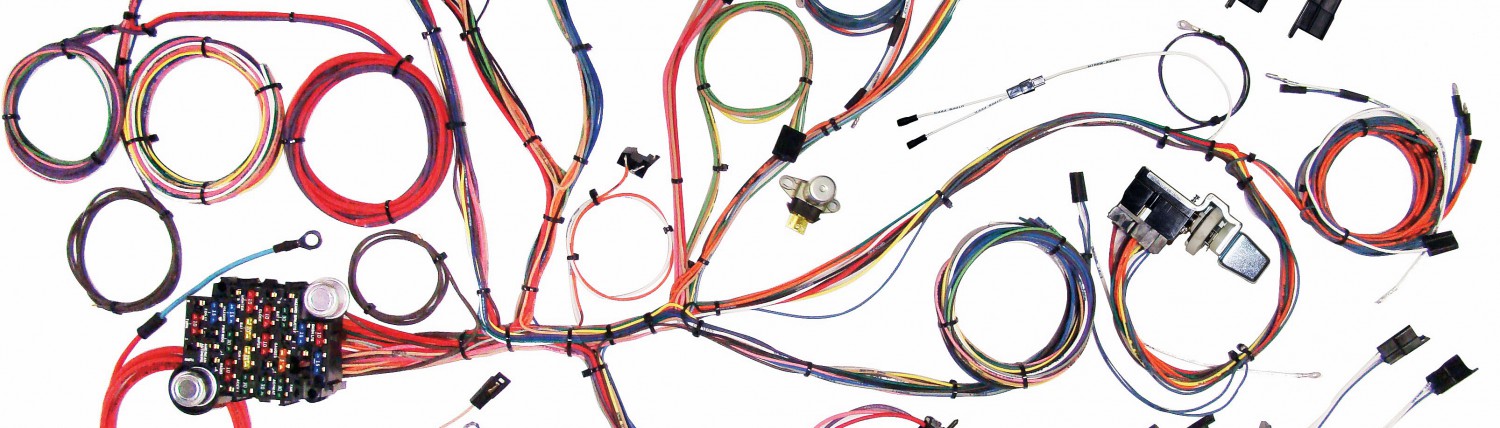

JDK’s process is thorough with assistance from quoting to packaging. We will assist in the design of communication, automotive, interface as well as MIL spec harnesses, drawings, samples and the like.

Only once samples approved and drawings signed off will production begin. Any updates any changes on drawings will be provided with the customer having their own slip for filing and query purposes.

JDK Harnessing is dedicated to delivering on time with full testing done beforehand. Terminal crimping, soldering, insertion and tests are all done on site to ensure quality control.

Some of the products provided include:

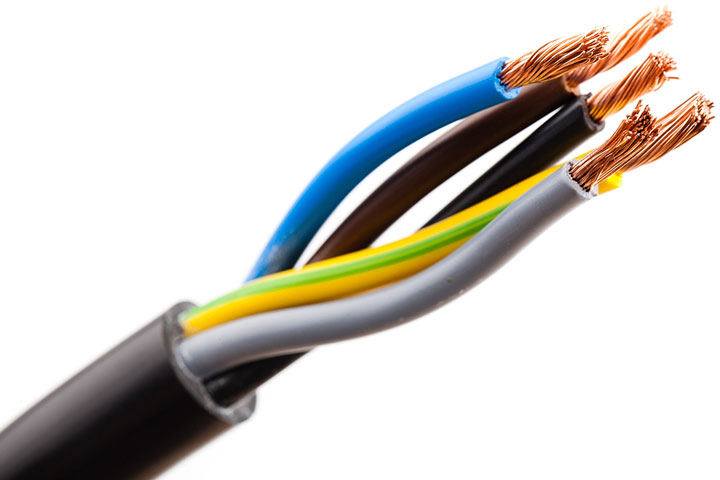

Wire:

Wire

Automotive, panel and silicone wire are all produced on site as well as Multi-core cable.

Heat Shrink:

Heat Shrink

Heat shrinking is an effective means of protecting your cabling with the fit preventing moisture and dust seeping in. It also lowers the risk of shock. Furthermore the range of colours available make heat shrinking a great tool for delineating harnesses.

Two services of heat shrink are available in the form of heat shrink and adhesive heat shrink. All are available in various colours and sizes.

Braided Sleeve:

Braided Sleeve

Braided sleeves protect wires from UV radiation, chemical degradation and abrasion. All available in a cost-effective manner.

Various sizes of braided sleeve can be produced in black.

Connectors and Terminals:

MIL Spec connectors

JDK can also supply you with a range of circular connectors including MIL Spec., Commercial grade and Splash/Water proof.

Automotive Connectors:

Automotive connectors

Connectors specifically engineered for automotive applications are also available through JDK’s bespoke service.